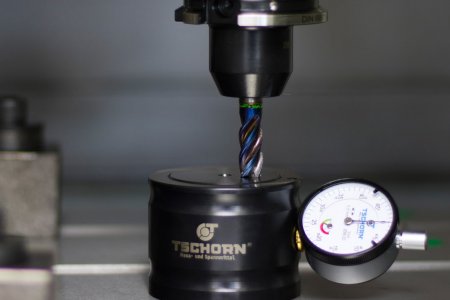

Mechanical zero setters

For determining the position of workpiece surfaces or tool surfaces in Z

Our mechanical zero setters are the perfect tool for determining workpiece surfaces or tool lengths in Z-direction at milling machines or lathes.

The zero setter is placed on the workpiece. The spindle has to be moved carefully onto the tracer until the dial gauge indicates „0“. The reference dimension 100 mm to the workpiece has been reached. A safety spring deflection of max. 2 mm is included.

The zero setter is placed on the workpiece. The spindle has to be moved carefully onto the tracer until the dial gauge indicates „0“. The reference dimension 100 mm to the workpiece has been reached. A safety spring deflection of max. 2 mm is included.

To allow lateral mounting, a zero setter with built-in magnets is also available.

Zero setter mechanical standard 50 mm height

Zero setter Micro 100 mm height

Perfect for measuring micro tools.

The mechanical zero setter is the standard version of our mechanical zero setters. It has a height of 50 mm and can be used for precisely determining the position of workpiece surfaces or tool lengths in Z direction on milling machines or lathes.

Like the standard version, the Micro zero setter is suitable for precisely determining the position of workpiece surfaces or tool lengths in the Z direction on milling machines or lathes. What distinguishes the zero setter Micro is its extremely sensitive probing surface, with which we even measured milling tools with a diameter of 0.1 mm without any problems. In addition, with 100 mm height, the mechanical zero setter is twice as high as the standard zero setter.

PDF-Download